SILCAPOR 1000

MICROPOROUS INSULATION MATERIALS

SILCAPOR 1000 – new possibilities in the SILCA product range also in the field of fireplaces and furnaces

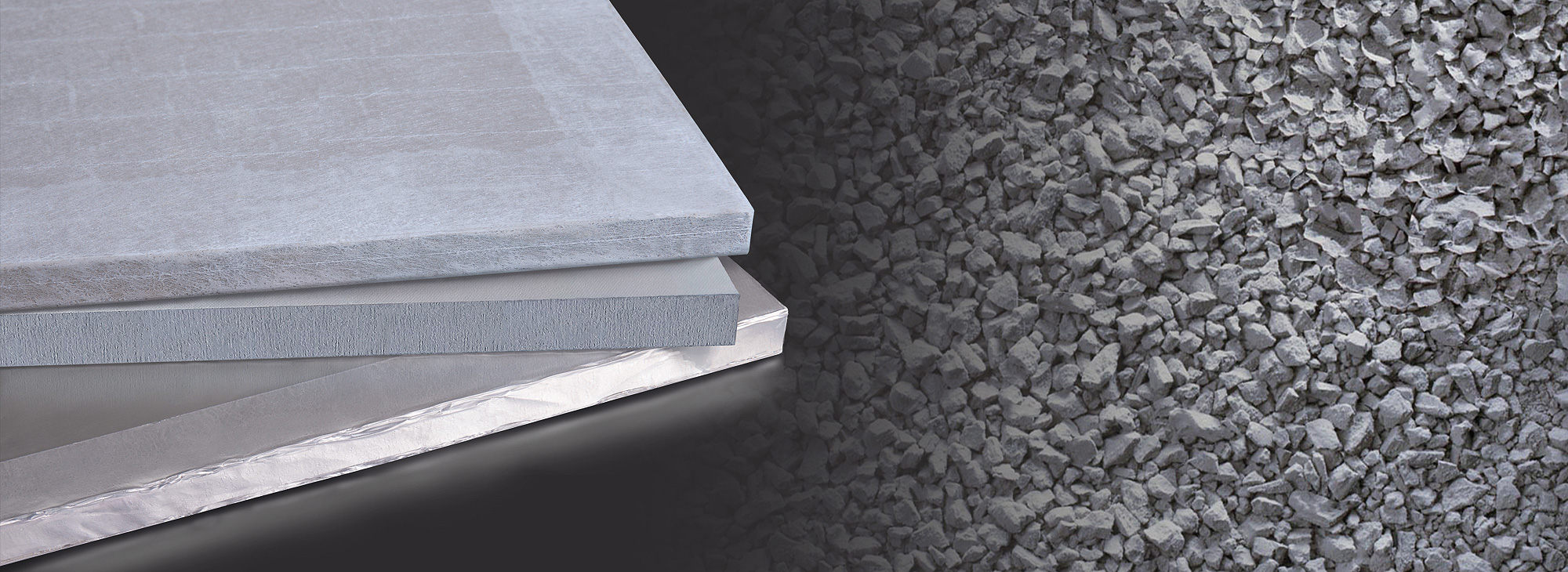

SILCAPOR 1000 is a light, microporous insulation material for back-up insulation with extremely good thermal insulation properties. SILCAPOR 1000 are inorganic boards based on highly dispersive, amorphous silica. According to WHO, the fibres used are not respirable and not dangerous according to Regulation (EC) No.1907/2006. The upper application temperature is 1000°C and pertains to the core SILCAPOR 1000.

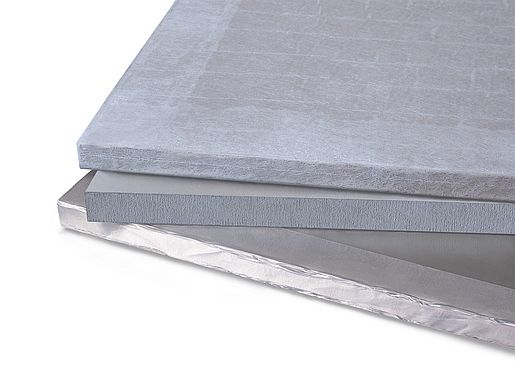

SILCAPOR 1000 is produced as a board and can be offered with an aluminium or glass fleece layer. The type of lamination should be selected according to the operating temperature and purpose. In addition to dust-free handling, depending on the variant, additional protection against moisture is available. SILCAPOR 1000 FT can be produced as customer-specific moulded parts due to higher bulk density.

SILCAPOR 1000 FP is a thin, flexible panel, laminated on both sides in aluminium foil and sealed under vacuum. Due to the different laminations, SILCAPOR 1000 FP panels are flexible and as SILCAPOR 1000 Q in a quilted design, can also be moulded for complex geometries. With rigid slats, the microporous thermal insulation material is also available as SILCAPOR 1000 SF as foldable panel. Here too, it is possible to plan a layer with insulation material.

Due to the high porosity, SILCAPOR 1000 products are industrially processed. For further processing requests, please contact us.

SILCAPOR 1000 in all its available variants, fills the gap where high-quality, very thin insulation materials are needed, for chimney furnaces, heating inserts and fuel boilers. The material is resistant to thermal and cold shocks and has only very little thermal shrinkage.

All variants ensure extremely good thermal insulation properties, the material is light and easy to prepare for the final assembly.

SILCAPOR 1000 – the solution for modern fireplaces, stoves, and biomass boilers - effective and flexible protection and safety

SILCAPOR protects components, reduces surface temperatures, and enables reduction in distances inside and outside of fireplaces. Regulating and control elements can be protected from high temperatures just as easily as, for example, electrical or fuel-specific lines and connections. In addition, SILCAPOR 1000 also protects the components of hot water preparation in fireplaces and biomass boilers.

SILCAPOR 1000 is available in following dimensions:

SILCAPOR 1000 Length 1000 mm Width 650 mm Thickness 10,15,20,25,30,40,50 mm

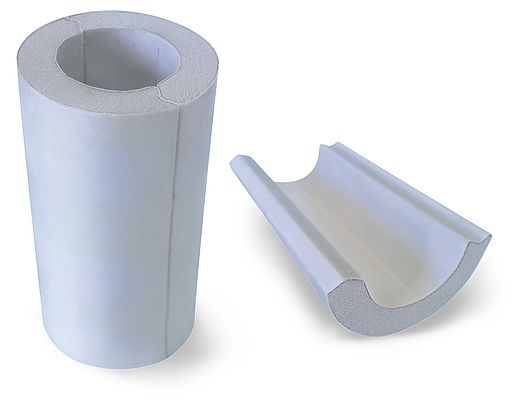

SILCAPOR 1000 RS Pipe segments Length 500 mm Diameter 13 to 300 mm

SILCAPOR 1000 P Standard 1000x600 mm Maximum 2,700x700 mm Thickness 5-50 mm

SILCAPOR 1000 SF Length 1000 mm Width 600 mm Thickness 10-50 mm

SILCAPOR 1000 Q Length 1000 mm Width 600 mm Thickness 3,5,6,8,10,12.5 mm

Special sizes and – thicknesses upon request

SILCAPOR 1000 has to be stored and processed in a dry place and can be stored indefinitely. SILCAPOR 1000 has to be protected against moistening due to humidity. Vapour diffusion does not affect the insulation material. A suitable surface treatment or surface lamination can prevent or significantly reduce penetration of liquids.

Silca Service- und Vertriebsgesellschaft für Dämmstoffe mbH

Elberfelder Str. 200a

40822 Mettmann

Phone +49 2104 9727-0

Fax +49 2104 76902

Email info@silca-online.de