SILCAPAN-KE 400 Composite elements

Large-size constructional elements

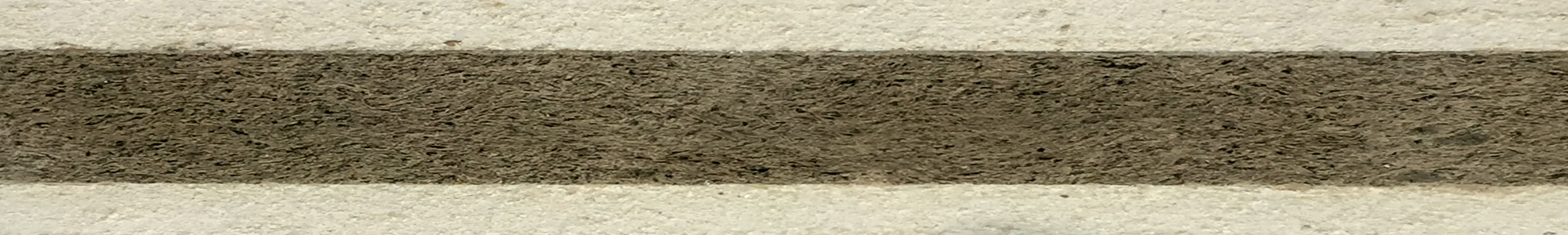

SILCAPAN-KE composite elements are large-size constructional elements used for heat treatment plants. SILCAPAN-KE 400 consists of two rigid cover panels of SILCAPAN 400 and an insulating core of the solid SILCAMIN 55-40 boards.

Construction

For SILCAPAN-KE elements and SILCAPAN insulating boards the mode of construction with a steel framework construction has proved itself in practical use. An appropriate carrier framework in the form of a steel frame structure is envisaged. This should be designed in accordance with the statical requirements so that both the insulating boards and any fixtures can be supported.

The steel framework construction is to be dimensioned in such a way that the boards can lie on it all round to a width of at least 25 mm. With large spans of and in excess of 625 mm, supports or, as the case may be, props are to be provided in the panel area. The boards may not be trodden on. If it is necessary that they be walked on, separate honeycomb gratings are to be provided.

For mounting the boards on the framework structure there are a number of very different possibilities. However in every case the elements must lie on the framework structure all round and be fixed to it in a firm manner.

When selecting the mode of securing, account must be taken of the difference between the coefficient of thermal expansion of the mounting structure and that of the SILCAPAN elements/boards. The coefficient of thermal expansion of the KE elements is very small at approx. 5x10-6 K-1.

Special features

- large-size

- high strength

- good thermal insulation

- simple processing

Downloads

Clamp connections

The most cost-favourable solution is that of clamps/clips in the region of the butt joint. In this way the difference in thermal expansion and the manufacturing tolerance of the steelwork are compensated for in the simplest way. The elements are free to move beneath the clamping section.

Through bolts

Where securing is carried out with through bolts, the diameter of the holes in the elements and boards must be at least 2 –3 mm greater than the diameter of the bolts. In order to avoid pointwise compression stress at the securing bolts, clamping strips should be used if possible or washers of an adequate size, e.g. approx. 60 x 60 x 3 mm.

Distances between securing bolts

The distances between the securing bolts when using clamping strips (bent sections) should not be more than 500 mm or, as the case may be, 100 mm at the corners of the clamping strips. In the case of through bolts with large washers the distance between the bolts should not be more than 300 mm.

Seals

The elements or boards can be backed with an adhesive tape (adhesive on one side) of SILCAWOOL 120 stripe in accordance with the pressure situation and ambient atmospheric conditions.

Storage

SILCAPAN-KE elements have to be stored dry and without risk of frost under cover. Changes to the thermal properties can come about particularly in the region of the adhesive bond if the elements are permitted to take up moisture or are stored incorrectly. The elements should be stacked on pallets and covered with foil so that the moisture content in the stack remains uniform.

Machining

The elements can be machined using conventional woodworking machines and tools with carbide cutting elements. The use of a dust extraction system is recommended when relatively large numbers of elements have to be machined. Since we have an excellently equipped machining shop, we can machine the elements in accordance with your particular requirements. In this way cutting work taking a lot of time and money on the building site can be saved.

Painting and coating

The elements represent an open-pore insulating system. For this reason account should be taken of the changes to the vapour diffusion resistance values that will come about with a decorative paint on the outside. There should be always a downwards pressure gradient from inside to outside. If necessary the resistance should be balanced out on the inside with the aid of impregnation. The surface must be prepared appropriately before paint is applied. Moisture barriers on the outside, e.g. in the form of sheet-metal cladding or film, will lead to the formation of condensation in the elements.